[For Immediate Release - 15th December 2022]

N'GENIUS solution on the horizon for oil, gas and LNG industry.

An innovative range of high strength austenitic stainless steels has been developed that will revolutionise the design and construction of onshore and offshore facilities in the oil, gas and liquefied natural gas (LNG) sector.

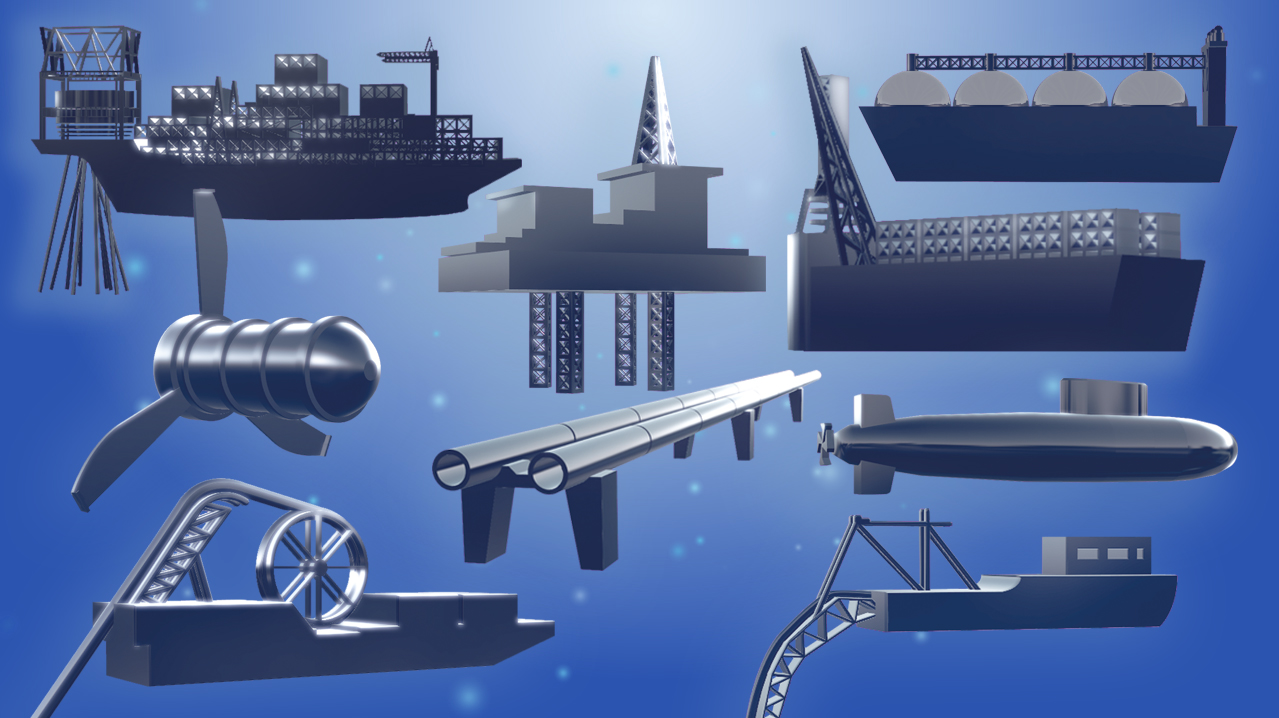

The global demand for LNG is projected to reach 700 million tonnes per year by 2040 fuelling the need for greater LNG infrastructure including import receiving and export terminals, FLNG vessels and LNG carriers. Since these facilities are being designed with larger capacities and operating under increasingly more challenging conditions, advanced materials technology is required to maximise performance, reduce carbon emissions and optimise through-life costs.

Fortunately, an N'GENIUS solution is on the horizon.

Patent protected in 30 countries around the world, the N'GENIUS Series™ is a complete 'family' of high strength austenitic stainless steels possessing major improvements compared to 300 Series stainless steels, and a highly economical alternative to various nickel-alloys.

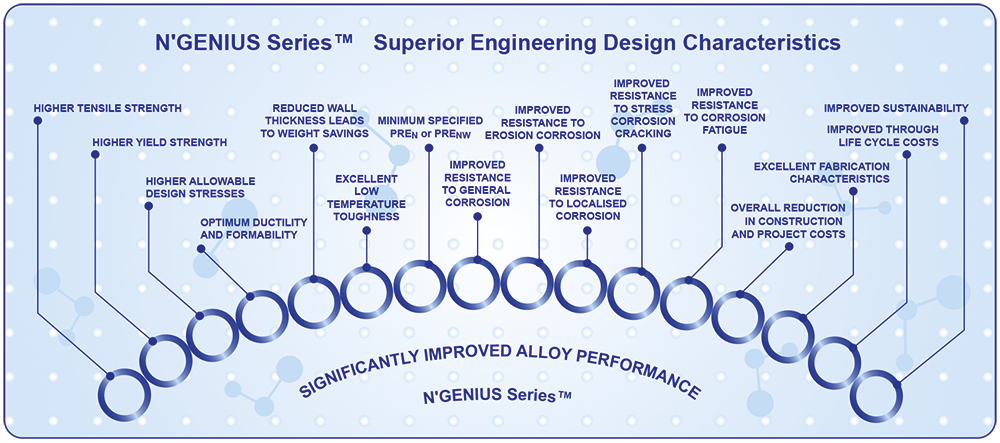

As with conventional austenitic stainless steels, the N'GENIUS Series™ has excellent ductility and toughness at sub-zero and cryogenic temperatures. But exceptionally higher strength and vastly superior corrosion resistance makes this new family an entirely different proposition.

Its unique combination of design characteristics provides key engineering advantages for the onshore and offshore industry.

LNG piping systems, engineered products, fabricated products and equipment can be developed and manufactured with reduced wall thicknesses, offering the potential to make products and equipment lighter and smaller, significantly reducing topside weight and helping facilities overcome space and height restrictions. Any space savings would also improve accessibility regarding servicing and maintenance, repairs, upgrading or replacement work on products and equipment in the future.

In particular, large facilities with extremely heavy topsides including floating production storage offloading (FPSO) vessels, FLNGs and upstream fixed platforms, would greatly benefit from the design and construction advantages that the N'GENIUS Series™ can provide. This includes the potential to reduce the overall construction time and costs, as well as benefitting from easier handling and lower associated transportation costs.

Dr C.V. Roscoe, the inventor of the N'GENIUS Series™, said:

"Some of these larger facilities can have topsides weighing more than 50,000 metric tonnes, which has a major impact on the design and construction cost of oil, gas and LNG projects.

"The N'GENIUS Series™ has an infinite range of Alloy types, variants and grades and is perfectly suited for all the different material specifications, scopes of work and products including piping systems, pumps, valves, modules, vessels and tanks. Therefore, the potential to optimise the weight and space of all these components, and in turn reduce costs, could be invaluable. It really is the total system material."

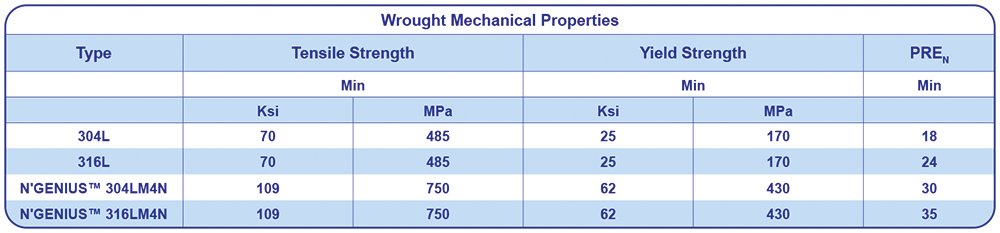

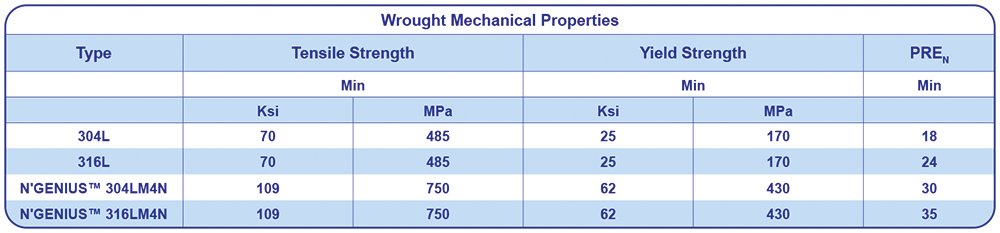

The weight-saving benefits provided by the N'GENIUS Series™ are achieved from superior wrought mechanical strength properties. For example, the minimum yield and tensile strength of the N'GENIUSTM 304LM4N and N'GENIUSTM 316LM4N grades are typically 2.5 and 1.5 times higher respectively compared to the minimum strength values of conventional 304L and 316L. This enables the N'GENIUS Series™ to have significantly higher allowable design stresses than conventional austenitic stainless steels.

Similarly, the higher minimum Pitting Resistance Equivalent (PRE) values for N'GENIUSTM 304LM4N and N'GENIUS TM 316LM4N grades compared to those for 304L and 316L produce significant improvements in the localised corrosion and general corrosion resistance. This enables products and equipment to last longer, facilities to be designed for a longer service life, and projects made more sustainable and cost-effective.

Furthermore, the extensive range of alloy types, variants and grades which form the 'family' of grades in the N'GENIUS Series™ make it suitable for all products, in all service conditions and in the harshest process media environments.

The N'GENIUS Series™ will also help accelerate the wider implementation of carbon capture and storage (CCS) technology. Inevitably, the addition of onboard CCS for upstream fixed platforms, FLNGs and FPSOs means additional topside weight, volume and space. So a reduction in the weight and size of onboard CCS systems, as could be achieved with the N'GENIUS Series™, would make this green technology become more feasible and play a fundamental role in driving down carbon emissions.

The N'GENIUS Series™ can be manufactured in both wrought and cast forms, in an extensive range of products for the oil, gas and LNG industries. These include pipe, tube, fittings, flanges for piping systems, modules, heat exchangers, umbilicals and line pipe for risers, flowlines, pipelines and manifolds. N'GENIUS technology can also be applied to engineering products including pumps and valves, fabricated products such as vessels and tanks, and specialist products including casing and tubing for Oil Country Tubular Goods (OCTG).

An N'GENIUS technology with total system capability, truly living up to its name.

The N'GENIUS Series™ is available to be produced under licence by premier manufacturers of stainless steel products. End clients, engineers and manufacturers interested in discovering more about the N'GENIUS Series™ can visit www.ngeniusmaterials.com or its sister company United Pipelines (www.unitedpipelines.com).

Assets for use

[ N'GENIUSTM Logo - NOT FOR PRINT ]

N'GENIUSTM Logo Guidelines

[ Supporting Illustrations - NOT FOR PRINT ]

Note: These assets are not to be used for any printed collateral. For high resolution, print-ready assets, please contact the Media & PR team. These assets are owned by or licensed to us and are subject to copyright protection and other laws for the protection of Intellectual Property.

Contact Details

Philip Roscoe - Media & PR

Email. philip.roscoe@ngeniusmaterials.com

Tel. +44 (0) 33 33 447 610

Paul Harrison - Sales Director

Email. paul.harrison@ngeniusmaterials.com

Tel. +44 (0) 33 33 447 602

About N'GENIUS Materials Technology

N'GENIUS Materials Technology, based in Cheshire, England, is a materials technology company, specialising in the invention of next-generation stainless steels for use across the world. The N'GENIUS Series of High Strength Austenitic Stainless Steels is the complete reinvention of austenitic stainless steels, designed specifically to supersede and replace many of the conventional 300 Series grades through increased strength and vastly improved corrosion performance. For more information visit www.ngeniusmaterials.com.

NOTES TO EDITORS

- 25Cr Super Duplex was invented by Dr Ces Roscoe whilst tasked by his then employer - Mather+Platt - with studying the effect of various alloying additions on the mechanical properties and corrosion resistance of Zeron 25. The new material became the first ever ‘super duplex’ stainless steel. Ownership of the technology has changed hands over the years, but it remains one of the leading super duplex stainless steels available in the market.

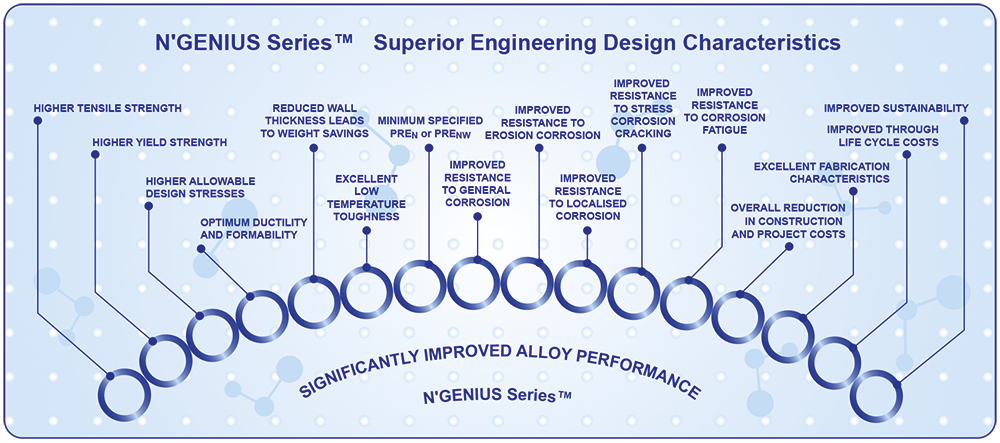

- Key Engineering Features of the N'GENIUS Series™ include:

- High Mechanical Strength with excellent Ductility and Toughness

- Higher Allowable Design Stresses

- Superior resistance to Localised Corrosion and General Corrosion relative to conventional Austenitic Stainless Steels

- Excellent Toughness at Ambient, Sub-zero and Cryogenic temperatures

- Reduced Wall Thicknesses, leading to Weight Savings and a decrease in Construction and Project costs

- Distinct minimum Pitting Resistance Equivalent (PREN or PRENW) values

- Patent and Trademark protected in the following countries:

Australia, Austria, Belgium, Brazil, Brunei, Canada, China, Finland, France, Germany, Hong Kong, Indonesia, Italy, Luxembourg, Netherlands, Norway, Malaysia, Mexico, Philippines, Russia, Singapore, Slovenia, South Africa, Spain, Sweden, Switzerland, UAE, UK, USA and Vietnam, with International Patents Pending in India, Japan, South Korea and Thailand.